Fuel Treatment

You are entitled to expect the best from XBEE Enzyme Fuel Technology. This enzyme-based fuel treatment offers a very wide range of benefits. Let us sum them up into three categories: cleaning fuel systems, saving money, and reducing pollution.

Cleaning your fuel tanks and engines

Engines do not burn 100% of the fuel. This leads to soot and toxic air pollution. Moreover, oxidized or contaminated fuel plugs filters and ruins injectors, which causes increased pollution, wasted fuel, higher maintenance costs, and shorter engine life.

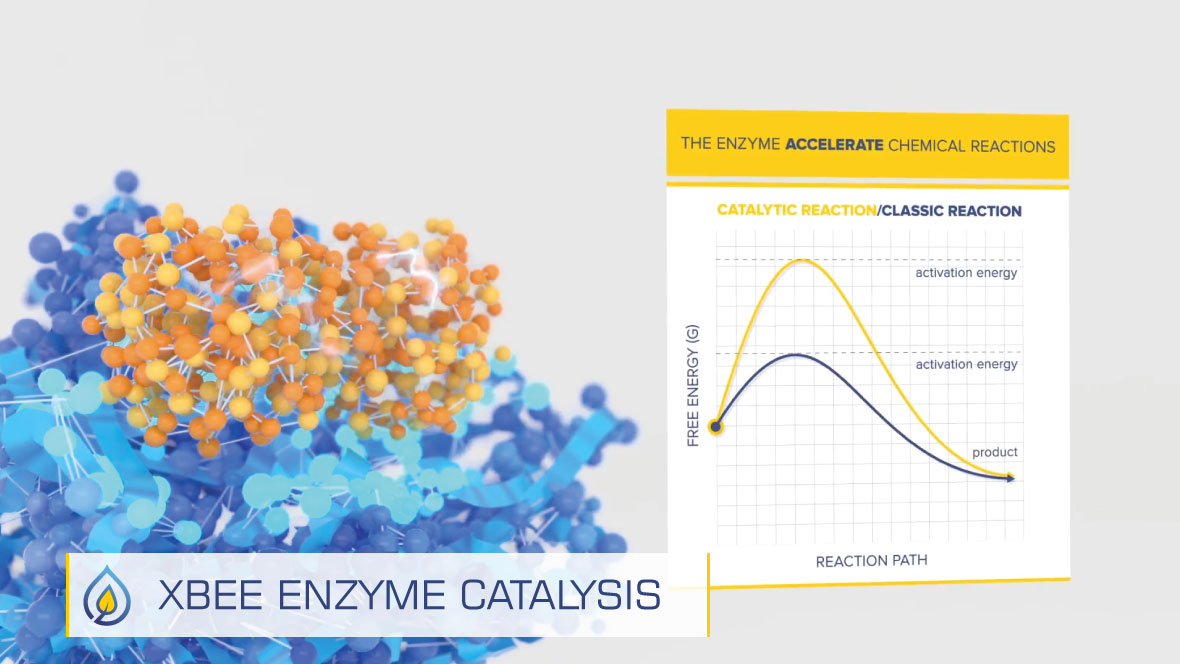

XBEE enzymes are naturally occurring catalysts. They act as surfactants when fuel is in motion and break down larger, slower-burning fuel molecules which are precursors to soot. Smaller molecules vaporize more completely during fuel injection. This leads to better oxygenation, and a more complete combustion process. As XBEE enhances fuel atomization and oxygenation during combustion, it reduces soot and toxic air pollution while improving fuel economy. XBEE also disperses water as harmless microscopic drops along with breaking down fuel-derived organic contaminants which are burned off in the engine, protecting filters and injectors, reducing maintenance costs, and increasing engine life.

Paying for itself and saving you money

As a combustion catalyst, XBEE Enzyme Fuel Technology’s action of improving fuel atomization and hyper-oxygenation of the fuel charge during combustion improves engine efficiency. Less fuel is needed to accomplish the same work.

The savings from using less fuel pays for the cost of treatment with XBEE. All the other benefits, including reducing CO2 emissions along with reducing toxic soot, carbon monoxide, NOx, and SOx, come for free.

With XBEE Enzyme Fuel Technology, you can reduce your carbon footprint and save money.

Moreover, once XBEE fuel treatment has cleaned up the tanks and engines, additional financial advantages become clear:

- increased intervals between maintenance services

- less frequent or even no need for tank and injectors cleaning

- extended life of fuel filters, injectors, pumps, exhaust valves, pistons, and rings

- less down time for engine maintenance and repairs

- lower oil and filters consumption

- reduced invoices!

Improving your environmental footprint

Among many benefits compared to chemical additives, the main benefit of XBEE Enzyme Fuel Technology for the environment is its great capacity to reduce all greenhouse gas emissions. Indeed, according to the measurements performed by several independent laboratories, XBEE natural fuel treatment often reduces pollution due to CO, CO2, NO, NOx, SOx, and particulate emissions by more than double digit percentages.

The enzymes contained in XBEE weaken the structure of hydrocarbon molecules in fuels and particularly polynuclear aromatic hydrocarbons (PAH). The process facilitates more complete oxygen absorption during combustion, thus limiting the formation of soot and carbon deposits.

Warranty

One of the most important questions when dealing with expensive engines and parts is: is there a warranty on the products? Am I allowed to use it? That was our main concern right from the beginning, and we contacted all the major administrations and manufacturers at once.

In the petroleum industry, all types of fuels you can find on the market are formulated to comply with regulated specifications. For instance, you may find EN 590 for diesel oil in Europe, or ISO 8217 for heavy fuel oils worldwide.

XBEE Enzyme Fuel Technology should be used at the same ratio of 1 to 4,000 in all fuels at every refill or bunkering. XBEE is composed of more than 99% petroleum distillate (kerosene) and less than 1% is the proprietary blend of plant enzymes. That is less than 0.0025 ml of the organic enzyme solution in one litre of fuel. It is obvious why ALL fuel analyses that have been performed by accredited and independent laboratories such as Bureau Veritas, Intertek, Saybolt, SGS and others have always led technicians to the same conclusion: Fuels treated with XBEE remain in compliance with fuel standards and can safely be used in all types of engines.

Although these international standards are already recognized and certified by all major petroleum companies and original engine manufacturers, XBEE always goes a step further.

We asked an accredited laboratory to test XBEE in accordance with the Coordinating European Council standards for both diesel and petrol engines: CEC F-23-A-01, and CEC F-05-A-93 respectively. This European benchmark organization’s board consists of more than fifty automobile manufacturers, oil companies, and oil manufacturers. Naturally, once more, XBEE passed the test and we can proudly say that our enzyme biotechnology can be safely used in all engines: cars, trucks, tractors, buses, etc.

We also contacted all the main OEMs in the maritime industry. Some simply stated that our technology complies with fuel standards. Hence, they authorized the use of XBEE in their engines. Some required a more thorough analysis of XBEE before granting its use in their engines. And a few even tested our technology before reaching the conclusion that they should recommend the use of XBEE in order to prolong the life of their engines. Det Norske Veritas (DNV) is an international risk management service provider, whose in-depth analysis of XBEE natural ashless composition demonstrated that this enzyme-based technology is totally harmless to engines or their components. Years later, Veritas Petroleum Services renewed the analysis and confirmed the same.